DESIGN

Computer Science

The Computer Science team is working to develop the mobile application for the Ab-Inforcer II. This application will be able to control the Ab-Inforcer, store the user's training data, and provide an interactive training experience on the app while using the Ab-Inforcer.

ELECTRICAL DESIGN

Wireless Controls

The new design is being upgraded to be controlled wirelessly from a mobile application. The wireless control was designed to work using an Arduino nano 33 ioT. This microcontroller allows for the transmission of Bluetooth Low Energy signals to send feedback from the sensors and to receive controls from the mobile application.

Sensors

The sensors being used in this project are Flexiforce force sensitive resistors. These sensors were chosen due to their size, flexibility, and accuracy. The previously used sensors only alerted users when a threshold was crossed; however, the Flexiforce sensors provide enhanced measurements by allowing the user to see the exact force value applied at each point.

Power

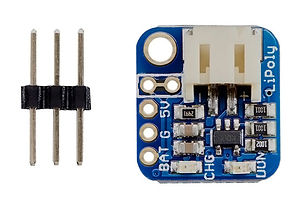

A large issue in the previous Ab-Inforcer was the frequent replacement of 10 AA batteries. To overcome this issue, a LiPo board was added to allow the user to recharge the battery pack using the micro USB port on the LiPo board, which will be placed in an easily accessible location.

Motors

The motors used in the previous design were too powerful and were wrapped in foam to dampen the vibration. The new motors will run off 3.7 V instead of 12 V, which will also greatly reduce the power consumption. Additionally, these motors will have variable speed settings, controlled by the Arduino.